The Auto parts production line has a production rhythm of 25 times/minute, or even faster. Compared with other ordinary manipulators, our equipment can achieve 24-hour non-stop operation through its high degree of automation, wide adaptability, and simple operation and maintenance, thereby improving production efficiency and reducing costs.

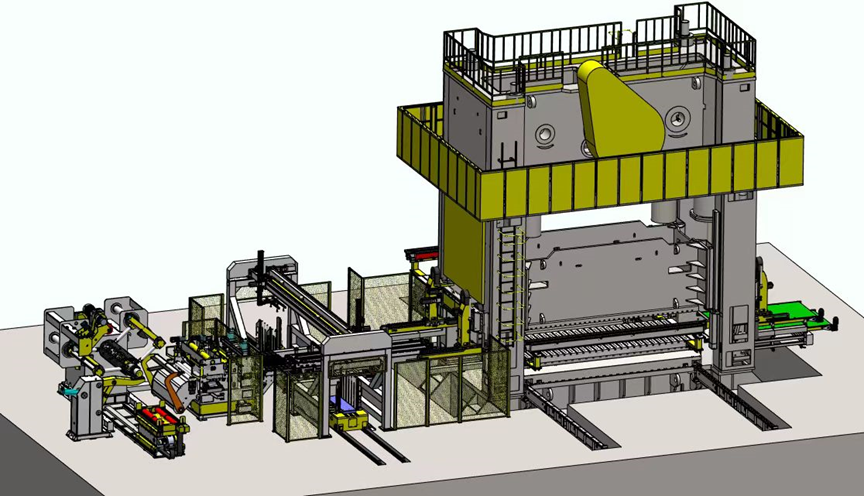

The customer’s 1600T continuous stamping line requires a large 3D transfer system to improve the productivity and efficiency of the whole line.

According to customer needs, we designed a large-scale 3D transfer system line to be linked with a press to achieve efficient, fully automatic multi-station production. The whole line is controlled by PROFINET communication, the product is highly safe and complies with CE standards.

Our 3D transfer system line is mainly composed of de-stacker, magnetic conveyor, and 3D transfer system.

We are a trusted manufacturer of stamping automation equipment production line, with our 3D transfer system equipment, we can urgently respond to the urgent needs for speed and quality.