In the realm of modern industrial automation, the quest for efficiency, precision, and speed is perpetual. Among the myriad of innovations that have emerged to meet these demands, double servo high-speed feeders stand as exemplars of transformative technology. Leveraging the synchronized power of dual servo motors, these feeders have redefined material handling in manufacturing processes, offering unparalleled performance and precision. This exploration delves into the capabilities and advantages of double servo high-speed feeders, elucidating how they are revolutionizing industrial automation.

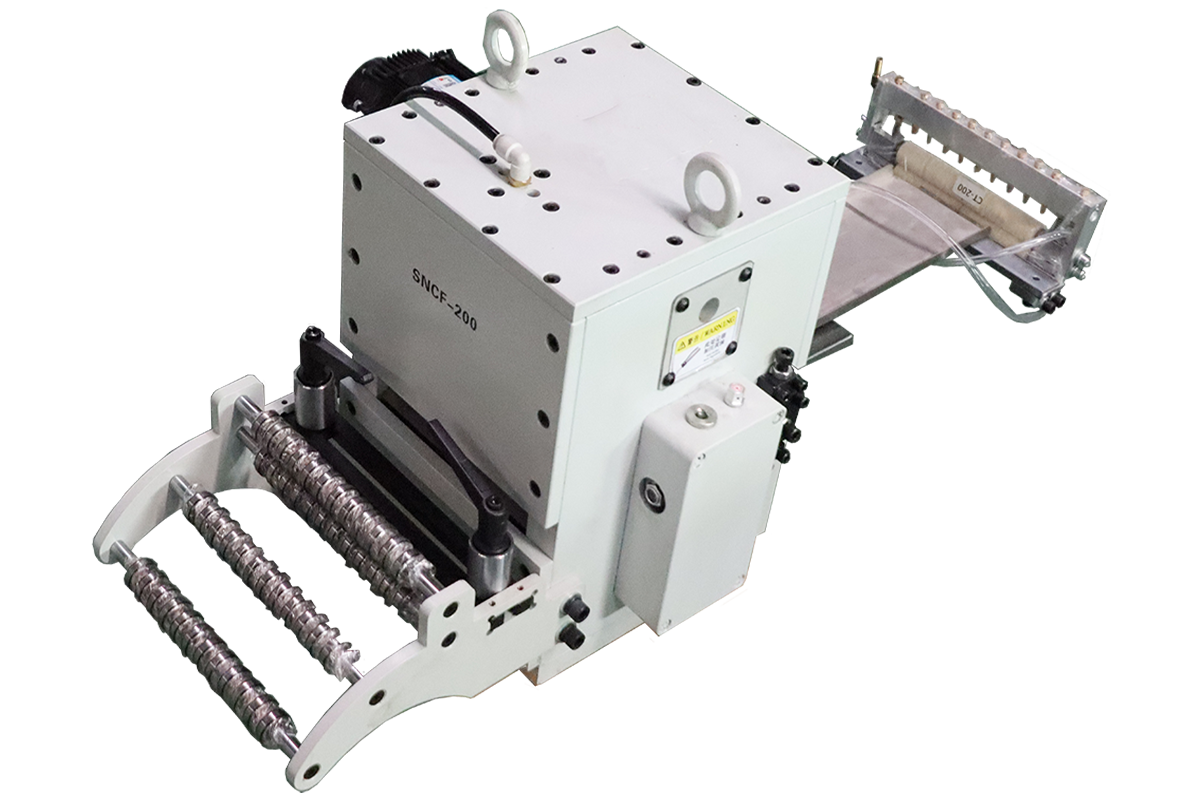

At the core of double servo high-speed feeders lies their dual servo motor configuration, which enables precise control over crucial parameters such as speed, acceleration, and torque. Unlike traditional feeders, which often rely on single servo or pneumatic mechanisms, the incorporation of two servo motors provides a level of flexibility and agility previously unseen in material handling systems. This dynamic control architecture empowers manufacturers to adapt swiftly to changing production requirements, whether it be accommodating high-volume assembly lines or executing intricate precision tasks with finesse.

The hallmark of double servo high-speed feeders lies in their ability to achieve remarkable speeds without compromising on accuracy or reliability. By harnessing the precision of servo motor technology, these feeders can navigate complex feeding patterns with sub-millimeter precision, ensuring consistent part placement and alignment. Moreover, the dual servo configuration facilitates rapid acceleration and deceleration, optimizing cycle times and maximizing throughput—a critical advantage in industries where time-to-market is paramount.

Precision is the cornerstone of modern manufacturing, and double servo high-speed feeders excel in this regard. Equipped with advanced feedback mechanisms such as encoders and sensors, these feeders offer real-time monitoring and correction, ensuring adherence to tight tolerances. Whether handling miniature electronic components or bulky industrial parts, the inherent precision of double servo high-speed feeders instills confidence in the integrity of the production process, reducing rework and minimizing waste.

The operational dynamics of double servo high-speed feeders are further enhanced by sophisticated control algorithms that optimize motion profiling and trajectory planning. Through precise synchronization and coordination of the dual servo motors, these feeders minimize vibration and inertia-induced disturbances, ensuring smooth and stable operation even in the most demanding applications. Furthermore, adaptive control strategies enhance system responsiveness, facilitating seamless integration into diverse manufacturing environments.

The transformative potential of double servo high-speed feeders extends beyond performance metrics to encompass operational efficiency and cost-effectiveness. Their modular design and plug-and-play compatibility with existing automation systems facilitate seamless integration and scalability, empowering manufacturers to adapt to evolving production demands. Additionally, the energy efficiency of servo motor technology translates into reduced power consumption and lower operating costs—a significant advantage in an era characterized by sustainability concerns.

Looking ahead, ongoing research and development efforts are poised to further enhance the capabilities of double servo high-speed feeders. Emerging technologies such as machine learning and artificial intelligence hold promise for predictive maintenance and adaptive control, preemptively addressing potential issues and optimizing performance parameters in real-time. Moreover, advancements in materials science and additive manufacturing techniques offer opportunities for lightweight, high-strength components, further enhancing the agility and durability of double servo high-speed feeders.

In conclusion, double servo high-speed feeders represent a paradigm shift in industrial automation, offering unprecedented levels of performance, precision, and operational efficiency. As manufacturing processes continue to evolve and grow increasingly complex, these feeders will undoubtedly play a pivotal role in driving productivity, quality, and competitiveness in the global marketplace. By harnessing the power of dual servo motors, double servo high-speed feeders are poised to revolutionize material handling and pave the way for a new era of manufacturing excellence.