Manipulator with 5 press speed frequency, to complete a transfer of 8.5 s. The production line can save about half the cost of normal production. Such as dishwasher, refrigerator, washing machine and other home appliances automatic production line can be applied.

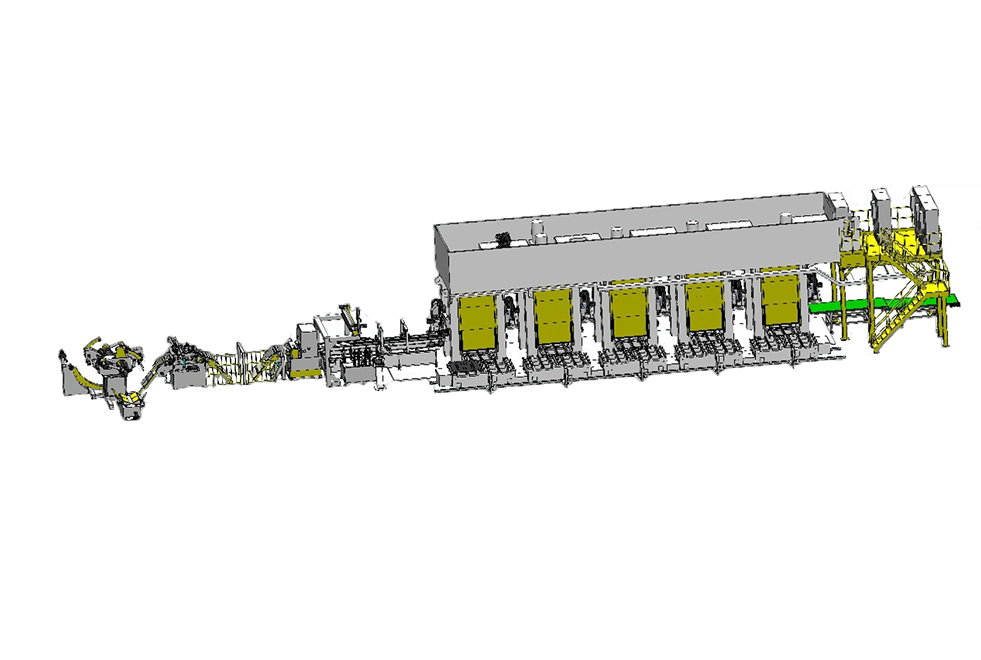

The 5-station press connection includes: uncoiling – straightening – servo feeding – shear blanking – magnetic conveying (including rotary reversing table, positioning slap) – 5 punches with 6 sets of triple speed transfer system – discharge conveyor belt. Suitable for automatic production of auto parts.

Continuous stamping automatic feeding line and all kinds of automatic stamping transfer system meet the application of TV, air conditioning, washing machine, kitchen appliances and other home appliance industries.

5 Station press line In addition suitable for the production of spare parts for dishwashers, also suitable for electronic industry, medical industry accessories and so on.