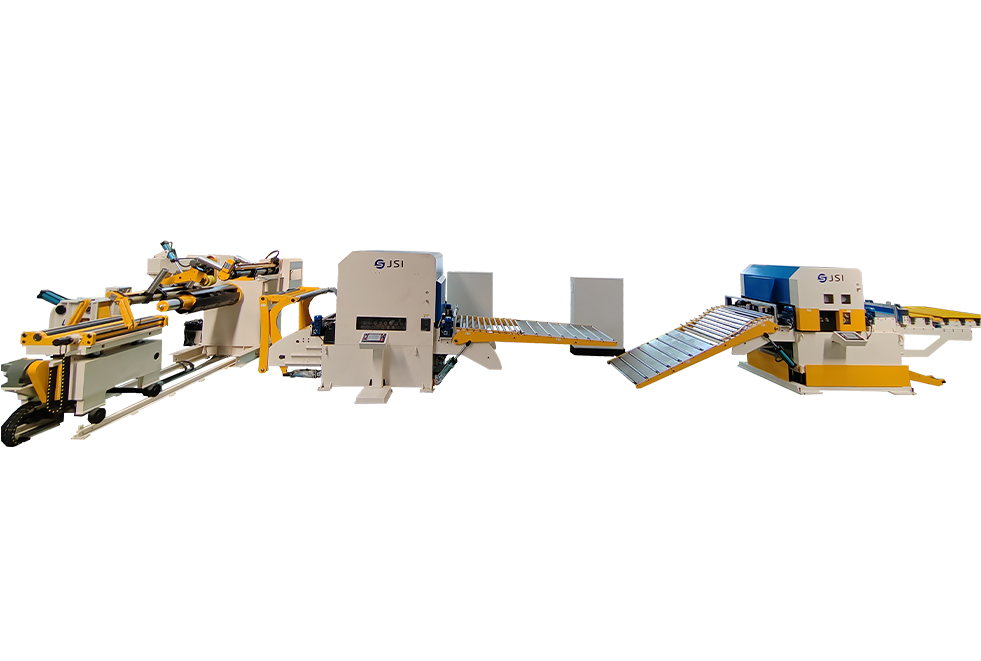

Our company’s new straightener applicable to automatic production lines with high flatness requirements, such as blanking line, laser cutting line and shearing line, especially for pre-punching processing of high-strength steel for automobiles, and post-punching processing of screens, saw blades, sprockets, etc.

The straightening accuracy of the new straightener can reach 0.1~0.5mm/m2, with high precision and strong stability.The normal straightener can generally only achieve a straightening accuracy of 1.5mm/m2

Products – Automobile Main Beam

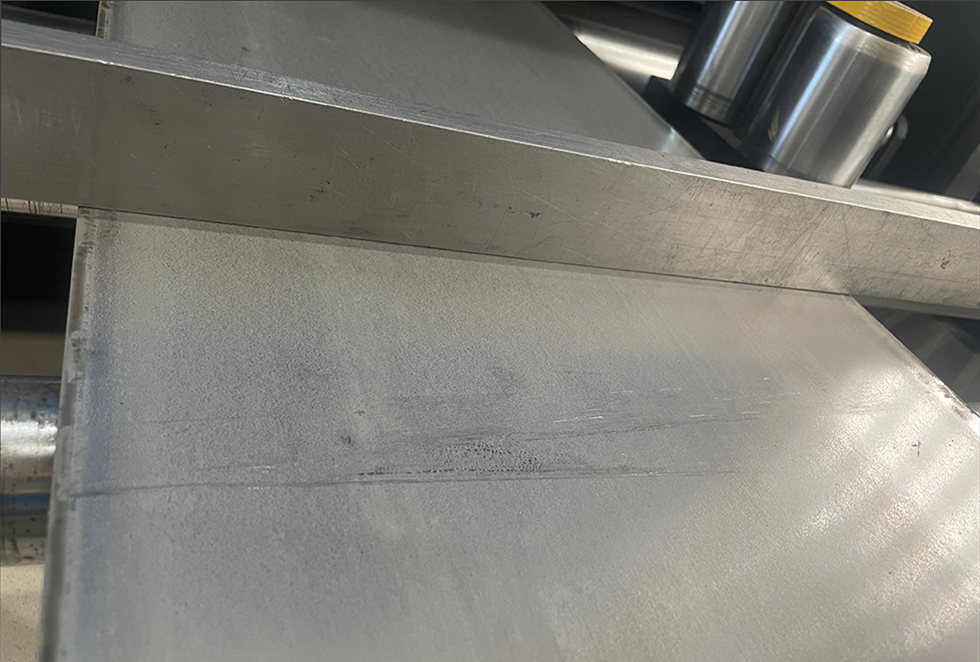

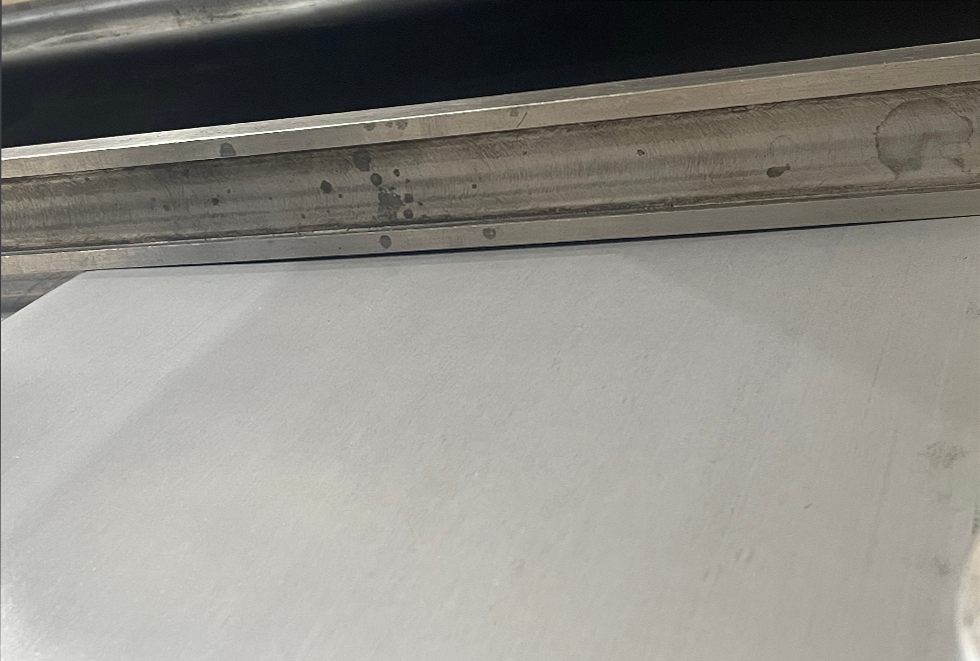

Problem – A crossbow appears perpendicular to the cross feeding, and the normal 3-in-1 de-coiler straighter feeder can’t solve the problem of horizontal leveling of the incoming materials, causing the product to fail.

Customer’s temporary solution – 100% inspection, 80% rework.

To remove coil crossbow, we use a straightener in which the pressure of each individual section rollers can be adjusted to level the coil in the rolling direction and across the coil width, and ultimately achieve high-precision leveling results, making customers worry-free and satisfied.

Raw Material Specification:

Material size: L*W*T: 2000*744*3.2mm

Yield strength: 650Mpa.

Tensile strength: 750Mpa.

Crossbow deformation: 4~7mm.

After straightening:

Flatness of the whole board: 0.15mm